National unified service hotline:0757-26616782

中文National unified service hotline:0757-26616782

中文Please enter keywords for search

Foshan Zhongshun Water Treatment Technology Co., Ltd

Tel: 0757-26616782 26628076

Email: sdzs@sinozs.com

Website: jackyxud.cn

Official account: zs water

Address: No. 3 East Hongye Road, Ronggui Rongqi Avenue, Shunde District, Foshan City, Guangdong Province

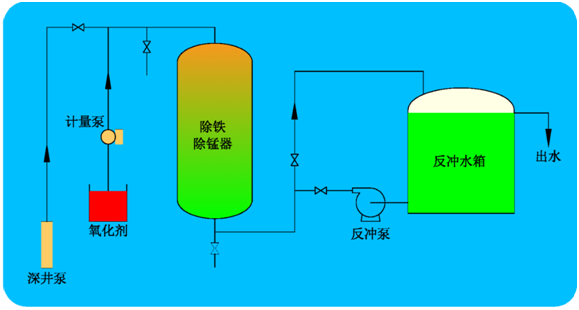

When groundwater contains both iron and manganese, the method of removing iron and manganese usually adopts a two-step treatment, with the first step being aeration to remove iron and the second step being aeration to remove manganese. The two-step treatment process usually requires the configuration of auxiliary facilities such as an intermediate water tank, intermediate water pump, and front and rear water level control, which makes the system complex and inconvenient to operate and use. The treatment process of Zhongshun Company adopts a one-step method, where a specially designed processor is filled with special filter materials. Groundwater can be simultaneously removed from the water by passing through the filter materials, without the need for a separate aeration process. The process and equipment will become very simple.

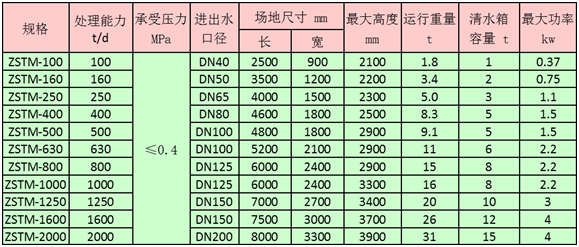

Main technical parameters:

Suitable for groundwater with excessive iron and manganese in raw water,

Raw water quality: iron ≤ 20mg/L, manganese ≤ 5mg/L, pH value neutral,

The effluent water quality is ≤ 0.3mg/L for iron and ≤ 0.1mg/L for manganese, meeting the national standards for drinking water

Iron and manganese content requirements:

The raw water pressure is ≥ 0.1MPa, but not higher than 0.6MPa,

Operation mode: 24-hour continuous operation, timely recoil,

Automatic operation control mode, compatible with manual operation,

The main material is stainless steel 304,

Working pressure 0.6MPa,

The material of the supporting pipeline valve is plastic or other corrosion-resistant materials,

Backflush method: The water pump backflush,

Power supply 380V, 50Hz.

Source of backwash water: backwash water tank.

Site requirements:

Underground water purification equipment for iron and manganese removal cannot be placed outdoors. In areas where ice can form, the equipment must be placed indoors and equipped with heating facilities. The site for placing underground water iron and manganese removal equipment should be solid and level, and the equipment should not be shaken after placement. Drainage ditches should be set up around the equipment. The drainage ditch should be able to adapt to the discharge requirements of maximum flow during backwashing.

The underground water iron and manganese removal equipment with automatic operation function requires the use of AC power supply.

explain

The effluent of the one-step groundwater iron and manganese removal equipment can be used in situations where hygiene indicators such as the total number of bacterial colonies in drinking water and swimming pool water have requirements. The treatment process uses disinfectants to oxidize iron and manganese, and the treatment process already has disinfection function, without the need for separate disinfection processes.

When there are hygiene requirements, the backwash water tank usually needs to be equipped with a stainless steel water tank. If conditions permit, a clean water tank can be used instead, and the capacity of the clean water tank cannot be less than the requirements listed in the table below. When there are hygiene requirements for water use, the clean water tank should be built according to hygiene standards. It is recommended not to use cement wall tanks.

The underground water iron and manganese removal equipment is a pressure bearing structure, and the outlet water carries a certain pressure. However, if the outlet water enters the water tank first, a Booster pump is required for re pressurization.