National unified service hotline:0757-26616782

中文National unified service hotline:0757-26616782

中文Please enter keywords for search

Foshan Zhongshun Water Treatment Technology Co., Ltd

Tel: 0757-26616782 26628076

Email: sdzs@sinozs.com

Website: jackyxud.cn

Official account: zs water

Address: No. 3 East Hongye Road, Ronggui Rongqi Avenue, Shunde District, Foshan City, Guangdong Province

In many parts of our country, groundwater contains excessive amounts of iron or manganese. When pumped out, this groundwater is colorless and transparent, and naturally becomes turbid after being left for a period of time, turning yellow or black in color, and some even have a foul odor. This type of groundwater must remove iron and manganese before it can be used for domestic or production water.

The groundwater iron and manganese remover is specifically used to treat groundwater with excessive iron and manganese content. After treatment, the iron and manganese content of the water meets the hygiene standards for drinking water.

The groundwater iron remover has 20 years of successful operation experience, with significant advantages such as simple process, low energy consumption, small footprint, stable performance, simple maintenance, and low comprehensive investment. It is widely used in urban, rural, construction sites, campsites, islands, mines, tourist attractions, field operations, and other domestic and industrial water treatment using groundwater as the water source.

The groundwater iron remover moves the external aeration and oxidation device of traditional equipment into the equipment, and the equipment can work only by relying on the residual pressure of the well pump. Its working principle and structure are different from common treatment methods such as aeration and oxidation treatment or manganese sand treatment, and the treatment effect is also different from traditional equipment: the treatment process of traditional equipment can see the process of water quality changing from clear to turbid, and then from turbid to clear, The water quality visible throughout the entire treatment process of the CTM groundwater iron remover is clear. In addition, equipment treated with manganese sand often needs to replace the filter material due to aging, while the filter material of CTM treatment equipment can be replaced for life without aging.

Principle: Excessive iron and manganese in groundwater exist in soluble low valence states. The groundwater iron remover sucks air into the groundwater, allowing oxygen in the air to fully mix with iron and manganese in the water. After separating the air and water through the diffuser, deep contact oxidation filtration is carried out in the filter bed to separate iron and manganese, and the effluent becomes clean water without iron and manganese.

The groundwater iron remover itself comes with an suction device and a reaction mixing device, which utilizes the residual pressure of the deep well pump as power to suck sufficient oxygen into the water without the need for additional auxiliary equipment such as an air compressor.

The iron and manganese in groundwater are trapped in the iron and manganese removal device, and these precipitates gradually block the filter material. After the equipment runs for a certain period of time, the iron and manganese precipitates are discharged from the body using a backwash method.

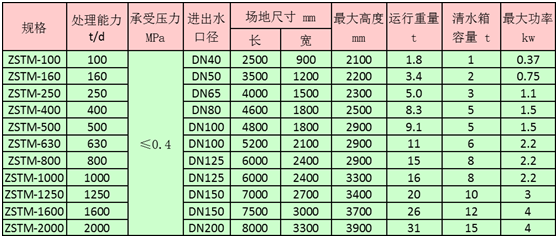

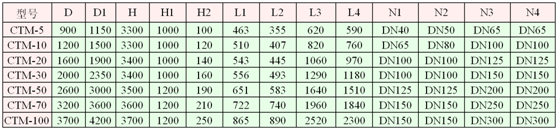

Main technical parameters:

Applicable raw water: Groundwater from deep wells, with iron content ≤ 20mg/L or manganese content ≤ 3mg/L, water temperature>10 ℃, and pH value>6.

Effluent water quality: meets the iron and manganese content requirements of the national standard GB5749 "Sanitary Standards for Drinking Water", that is, the iron content is ≤ 0.3mg/L, and the manganese content is ≤ 0.1mg/L. The treated water is clear and transparent, and will not turn yellow or black after long-term storage.

System composition:

● The groundwater iron remover is a gravity type treatment equipment, and the treated water flows out from the outlet at the bottom of the equipment by gravity. The water outlet has no pressure, so a clear water tank can only be set up below the equipment outlet, and the water can be pumped out for use. If the clean water tank is above the ground, a lift needs to be installed at the equipment outlet to lift the water into the clean water tank. The water storage of the clean water tank should also serve as backwash water, and the capacity of the clean water tank should not be less than the water consumption of the equipment for one backwash.

● The flow rate of the backwash water pump is required to be at least 5 times the operating flow rate of the equipment. Usually, the clean water pump that produces water cannot be used as a backwash pump, and a separate backwash water pump needs to be installed. The model of the recoil pump can be selected from the reference model in the technical parameter table, or other models with the same technical parameters can be selected.

● If the treated effluent is used for domestic drinking water, or there are requirements for microbial indicators in the water, it is necessary to consider adding water disinfection equipment.

● In some places, in addition to exceeding the iron and manganese content in water quality, other indicators of groundwater may also not meet the applicable water quality requirements of this equipment. In this case, pre-treatment of the well water is necessary before iron and manganese removal treatment. For example, for slightly acidic water, alkali should be added to adjust the water quality to neutral before entering the equipment for iron and manganese removal treatment.

● If the iron and manganese contents in the water are both high, it is usually necessary to consider using secondary treatment, namely primary treatment for iron removal and secondary treatment for manganese removal.

Operating costs:

The operating cost of the groundwater iron remover is only the electrical energy consumption of the deep well pump and the backwash pump. The number of starts of the backwash pump is related to the iron and manganese content of the water quality. Generally, it only needs to be started once a day, with a running time of about 5 minutes each time. This kind of electricity consumption can be almost ignored.